Tel: (301) 541-3662 (EMMA)

E-Mail: info@templeallen.com

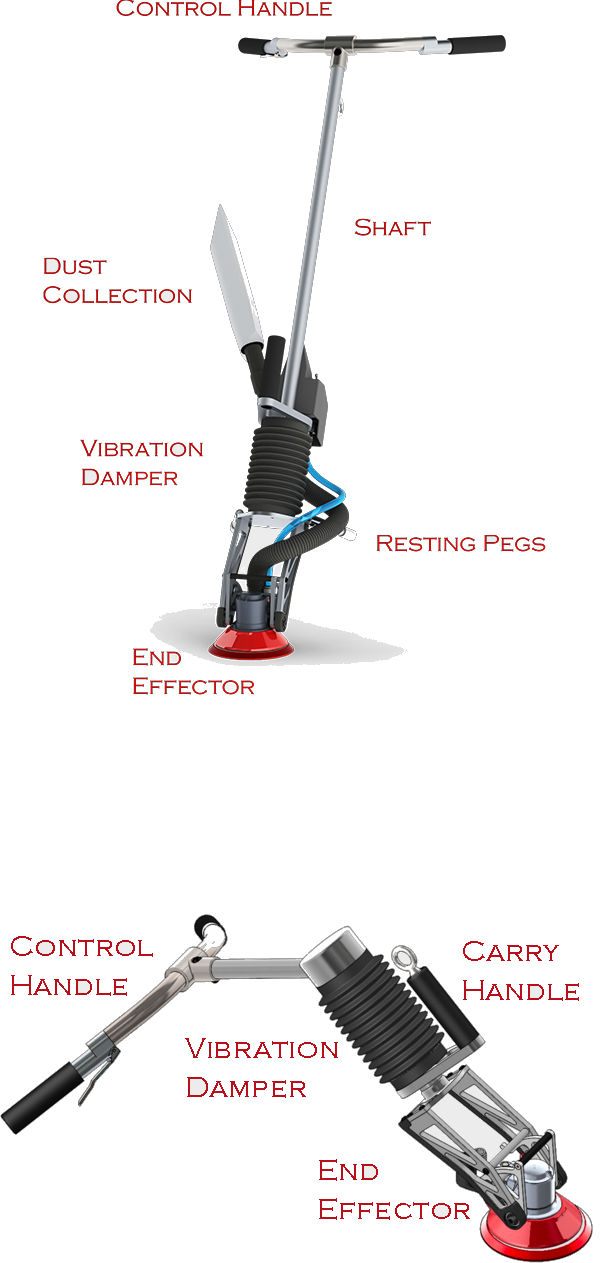

What SAM™ Is

Each SAM model* features a control handle, a shaft, an integrated dust collection system, a vibration dampening core, a carry handle, and an End-Effector which mounts the abrading tool being deployed.

*Dual Rotary model does not vibrate and does not require the Vibration Dampening Core.

The Control Handle incorporates Operator Presence Controls for the sanding head and the integrated vacuum. The handle’s ergonomic shape allows for a comfortable working position.

The Shaft enables artisans of any height to position the device in a comfortable way.

The Integrated Dust Collection System is suitable for all dry-sanding applications. Particulate and dust are captured at the sander and fed into 3M™ Clean Sanding Filter Bags or site-supplied vacuum hoses.

The Vibration Dampening Core is designed to meet stringent international vibration exposure restrictions, and minimizes the extent to which the vibration generated by the tool can reach the operator. Note that SAM dual rotary systems do not need the vibration dampening core, as rotary tools do not particularly vibrate.

The Resting Pegs allow the artisan to lay the SAM down during use, such as when changing sandpaper, while keeping the tool itself off the ground.

The End Effector is the mounting assembly which holds the tool(s) at the end of the Control Handle. Multiple configurations are available. The system has passive degrees of freedom (roll and pitch) that allow the sanders to stay properly positioned on the working surface.

note that the Tabletop SAM systems, while built with a shorter shaft, otherwise utilize many of the same components.

Copyright © 2019 - All Rights Reserved - Temple Allen Industries